History

The Quantum Plastics name represents quality and engineering expertise in plastic part production.

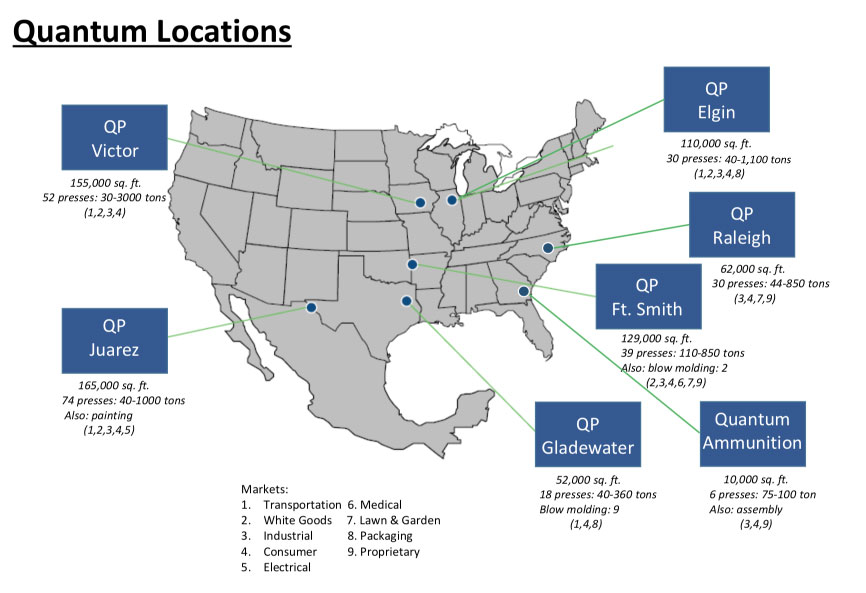

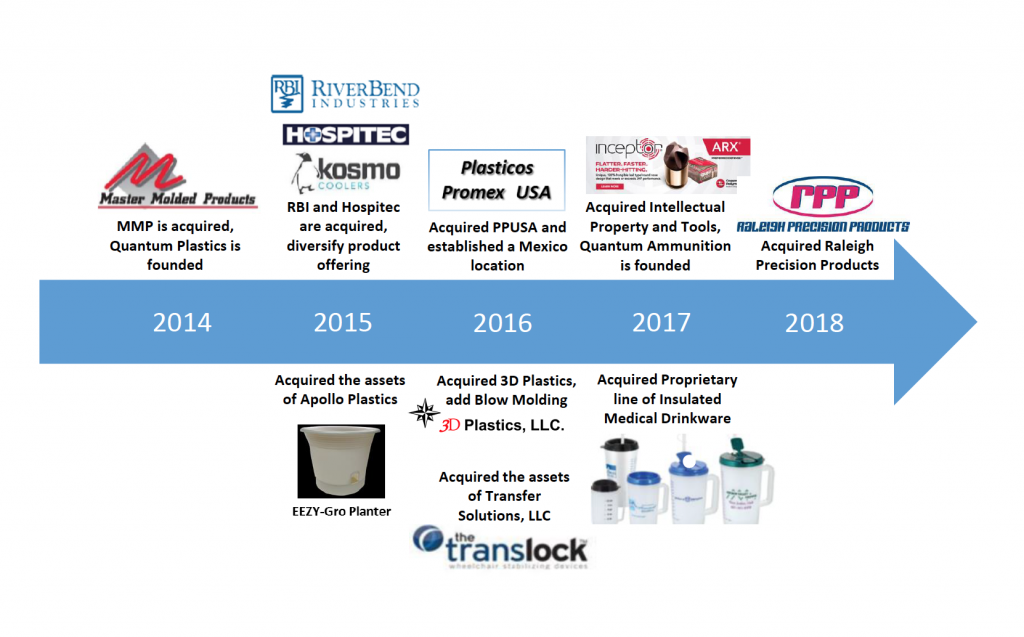

Beginning in 2014, Quantum Ventures established Quantum Plastics with the objective of creating a world-class plastics company centered in the idea of multiple product segments offering a variety of processes with a global footprint. This fundamental desire to be the undisputed leader in engineering and quality is what drives Quantum Plastics. Today, we are well on the way to achieving this objective. With seven (7) locations and growing we are here to serve our customers, employees and stakeholders with the desire to be the best at what we do!

From the water-cooler at the peewee football game and the food storage containers in your refrigerator (and maybe even part of your refrigerator) to the cluster on your dashboard, we are sure you have come across a Quantum Plastics product.

Elgin Division – 2014

Quantum Plastics Elgin Division was the first of the group and was created with the acquisition of Master Molded Products in 2014. Master Molded Products was a custom plastic injection molding company founded in 1946. Originally a tool and die making company, custom plastic injection molding capabilities were added in 1952. Today, this 110,000 square foot production facility in Elgin, Illinois makes injection molded plastic products for a number of diverse businesses; Automotive, Packaging, and Industrial-Consumer are just three key groups. The Elgin Division is TS 16949:2009, ISO 14001: 200 and ISO 9001:2008 certified and offers complete part design, injection mold design, automation of processes, and quality expertise to customize the solutions necessary for different and unique industry and market requirements.

Ft. Smith and Victor Divisions – 2015

Quantum Plastics’ added River Bend Industries in 2015 and formed the Ft. Smith and Victor Divisions. River Bend was among largest custom molders of thermoplastics and engineering resins with two ISO 9001:2008 certified locations in Victor, Iowa and Ft. Smith, Arkansas. These divisions were originally established in 2006 when the Ft. Smith location was acquired from Moll Industries. Then in 2008 it grew when it added the Victor, Iowa facility which was acquired from Spell Capital.

Together these facilities house 108 molding machines ranging from 30 to 3000 tons; all under 444,000 sq. ft. of manufacturing space. The Victor and Ft. Smith Facilities also offer in-house tool rooms for routine mold maintenance, repairs, and complete tool builds. Product fulfillment services cover complete concept review, engineering support, comprehensive quotation, tooling construction, production, warehousing, and distribution. Project engineers, sourcing specialists, and ISO certified staff identify the optimum methods to create customer product with one stop shop convenience.

Hospitec Division – 2015

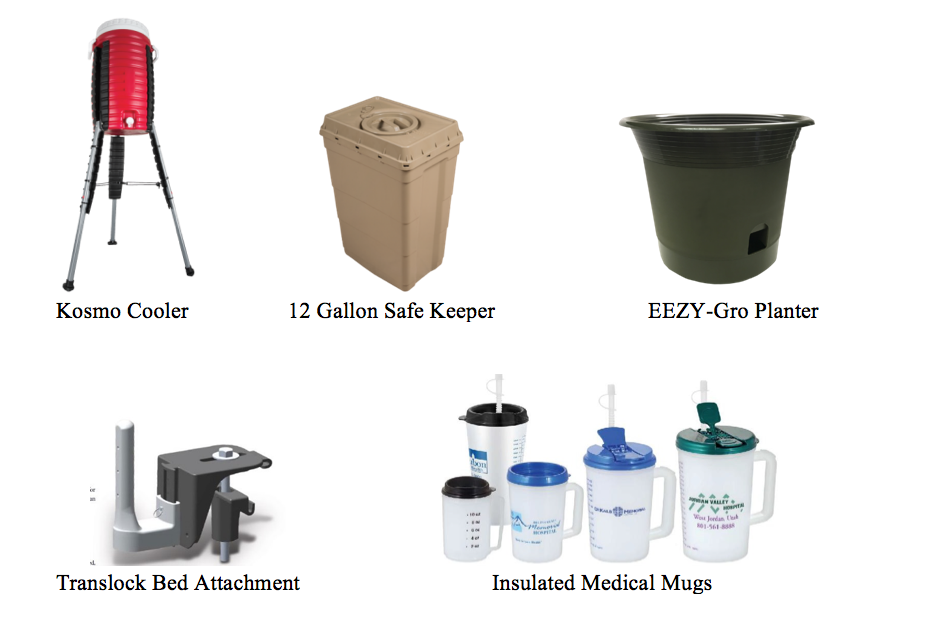

Included with the River Bend acquisition was Hospitec, USA. a proprietary products company whose products are proudly manufactured by the Victor and Ft. Smith Divisions, Hospitec and is known for its PG2 rated medical waste containers and related products. Production for the containers started in the United States in 2009. Kosmo Coolers, the only free-standing cooler is manufactured at Quantum Plastics Ft. Smith Division and marketed through the Hospitec Division. Cooler production started in the United States in 2010.

In 2015, we purchased the assets of Apollo Plastics, a manufacturer of household plastic planters often found in home improvement stores and moved manufacturing to the Ft. Smith Division. The Apollo Planters including the EEZY-Gro Planter™ are marketed today through the Hospitec Division.

In 2016, Quantum Plastics acquired Transfer Solutions, and expanded its product line to include Transfer Solutions’ Translock System product. Marketed under the Hospitec division and produced at the Quantum Plastics’ Victor Division, the wheel chair stabilizing device, the Translock System, is designed to assist a wheelchair user in the everyday tasks of transferring safely from the chair to a bed, shower or other application.

In 2017, Quantum Plastics acquired an insulated medical mugs product line from a well-known manufacturer who was exiting the segment. Complementing the other proprietary products in the Hospitec Division, Quantum Plastics now offers customized insulated medical mugs to hospitals and other medical facilities throughout the United States.

Juarez Division – 2016

Quantum Plastics, Juarez Division

Quantum Plastics added a Mexico manufacturing location in 2016 with the acquisition of Plasticos Promex, USA in El Paso, Texas with a maquiladora in Juarez, Mexico. Quantum Plastics’ Juarez Division, is known for injection molding plastic parts for a number of high profile brands in the appliance, consumer, electronics, industrial, and lawn and garden industries in a wholly owned maquiladora in Juarez, Mexico. It has earned a strong reputation within the plastics industry with its ISO 9001:2008 certification, highly skilled team of engineers and success with complex parts and engineered resins.

Gladewater Division – 2016

Also, in 2016, Quantum Plastics acquired 3D Plastics to form our Quantum Plastics Gladewater Division is an ISO 9001:2008 certified injection and blow molding facility. Gladewater’s injection and blow molding machines manufacture plastic parts for the automotive, food and beverage, and firearm industries. Most notably, Gladewater molds seat-belt parts and firearm ammunition components with their 23 molding machines. Many blow molds, as well as specialized tooling and trim machines, are built in house by the talented tool team. It also provides many secondary operations such as trimming, hot stamping and assembly. Some of the product packaging lines include brightly colored disposable drinkware and food and beverage packaging.Quantum Plastics, Gladewater Division

Quantum Ammunition – 2017

In the 4th quarter of 2017, Quantum Plastics created a new company Quantum Ammunition, LLC to develop and market a unique ammunition from an exclusive polymer-based material that eliminates the use of lead; the ARX® is a new projectile in every sense of the word: from the way it is manufactured, to its shape to the way it transfers energy to the target. To understand the ARX®, one needs to forget nearly everything they’ve been told about projectiles. The non-expanding ARX® is injection molded from a specially blended polymer-metal matrix. It is designed to penetrate most intermediate barriers without deformation and consistently achieves its terminal effect in soft targets and tissue. It is light weight; thereby producing reduced recoil and allowing for faster on-target follow up shots. The ARX® design and weight also means the projectile will penetrate through half as many walls as conventional lead-core projectiles; thereby, significantly reducing the risk of collateral damage should the user miss their intended target.

Raleigh Division – 2018

In the first quarter of 2018, Quantum Plastics acquired Raleigh Precision Products in Kenly, North Carolina. The Quantum Plastics Raleigh Division is renowned for proprietary plastic frames for the filter pleat separators used in commercial HVAC systems. These filter frames are used to hold pleated filers that are used in large commercial buildings, hospitals, etc. The Raleigh Division sells the frames, in dozens of versions, to large filtration companies. Raleigh also manufactures and sells various other consumer and industrial plastic components throughout the United States.